News

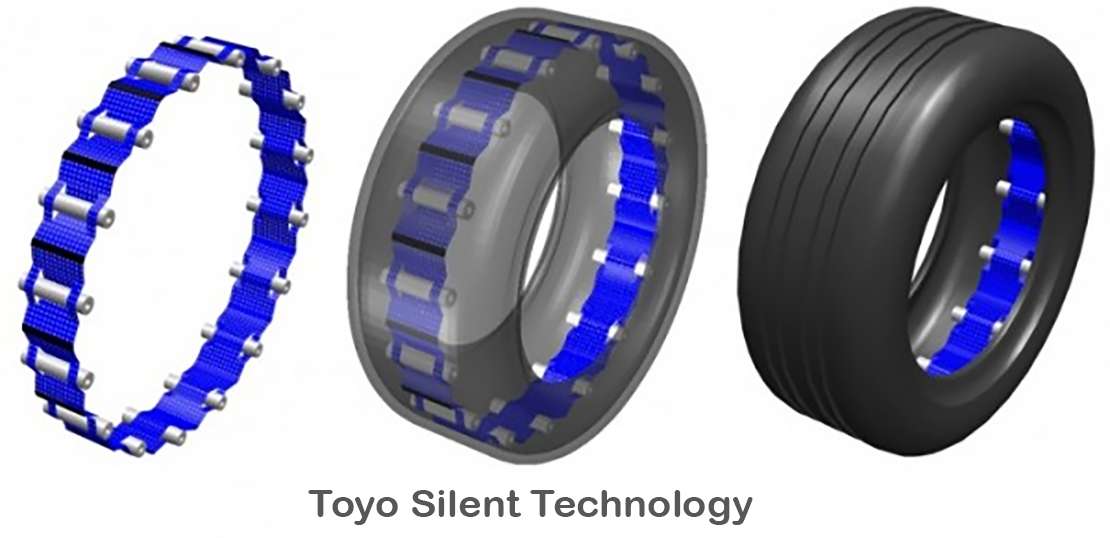

Toyo Silent Technology

25 Jul 2018

Toyo Tires has developed a new device that effectively reduces resonance in tire cavities, based on the new technology called “Toyo Silent Technology” to solve the issue of sound that is transmitted from the tire to the interior of a vehicle.

Hyogo, Japan – July 3, 2018 – Toyo Tire & Rubber Co., Ltd. President: Takashi Shimizu) announces that it has developed a new device that effectively reduces resonance in tire cavities, a source of interior noise, based on the new technology called “Toyo Silent Technology” to solve the issue of sound that is transmitted from the tire to the interior of a vehicle.

As hybrid vehicles become more popular, the mobility environment is becoming dramatically transformed as can be seen in the shift from the internal combustion engine that uses gasoline as a source of power for passenger vehicles, to motor drives. For that reason, there is a growing trend in the demand for high levels of comfort in vehicle interiors. We have accumulated abundant knowledge with regard to tires, the one part of a vehicle that touches the ground for the vehicle to travel. We will utilize that knowledge to incorporate Toyo Silent Technology into the products we will develop to provide drivers and passengers with a comfortable space with greater silence.

■Tire/Road noise that is transmitted via the tires

Noise is generated by the vibration of air. Tires mounted to the vehicle are structures that are internally filled with air. For that reason, input to the tires that is generated by contact with the road surface during vehicle travel causes the air inside the tire to vibrate. These vibrations are transmitted to the vehicle interior as noise via the axle.

Noise that is generated by air that is filled inside the tire being vibrated by the tire receiving external input (the road surface) is called tire cavity resonance, and is one source of vehicle interior noise. For example, when a vehicle is traveling at high speed over a road, and it drives over seams in the road,

one can hear a bumping sound. However, road-surface unevenness is inputted to the tire that is rolling. This is tire cavity noise that is generated by the phenomenon of vibrating air inside the tire.

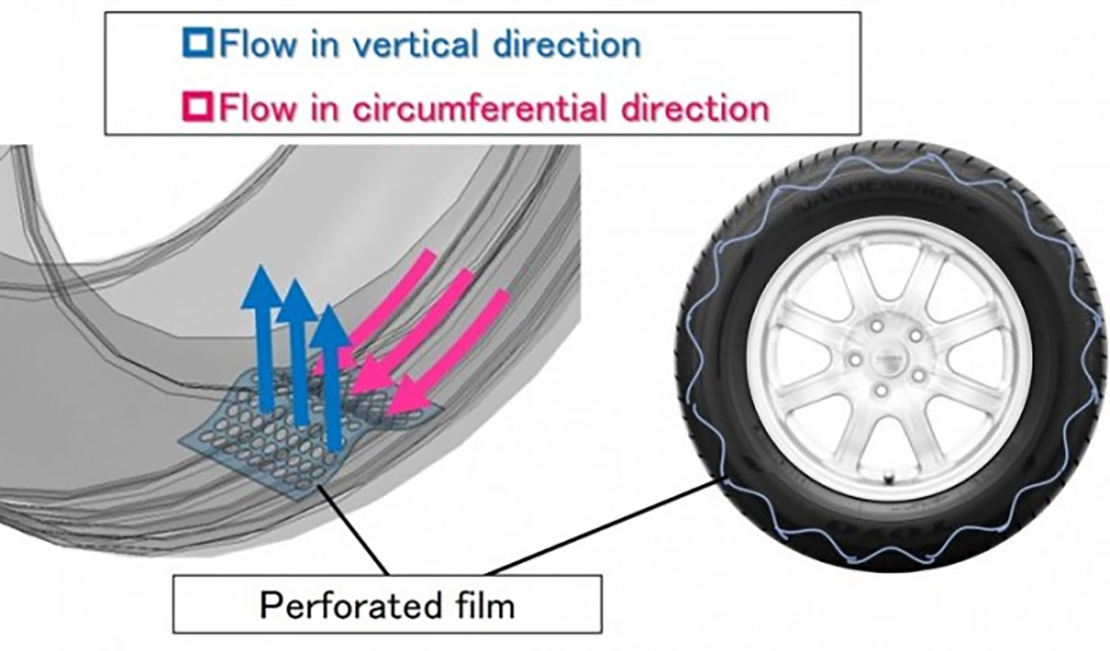

■ Discovery of air flow inside the tire

We conducted simulations to visualize what the status of the air inside the tire which is presumed to generate the noise, is like when the vehicle is actually traveling, in other words, when the tire is rolling in contact to the ground. Through these simulations, we ascertained that the air itself generated flow in the circumferential direction, and flow in the vertical direction.

One method for reducing tire cavity noise is the idea of internally mounting material that has a soundabsorbing effect was implemented in the tire industry as a leading technology. However, we focused on the fact that air flow is generated inside the tire so we incorporated our unique approach to reduce noise by utilizing the flow of air.

■ Arrangement of unique device to reduce noise

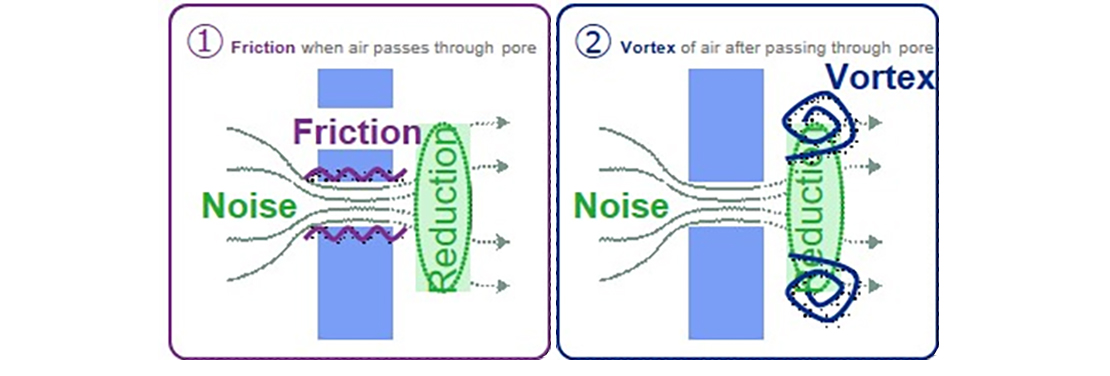

Originally, noise is reduced when it passes through the pore. There are two attenuation mechanisms, namely, friction is generated at the wall faces of the pore that the air passes through, and a vortex is generated by the sound passing through the pore.

Using the flow of air when sound passes through the hole further increases the noise-reduction effect so we arranged a porous film to face the flow of air (the pathway of the air) that we ascertained from visualization, and studied disposing a structure through which generated sound can pass.

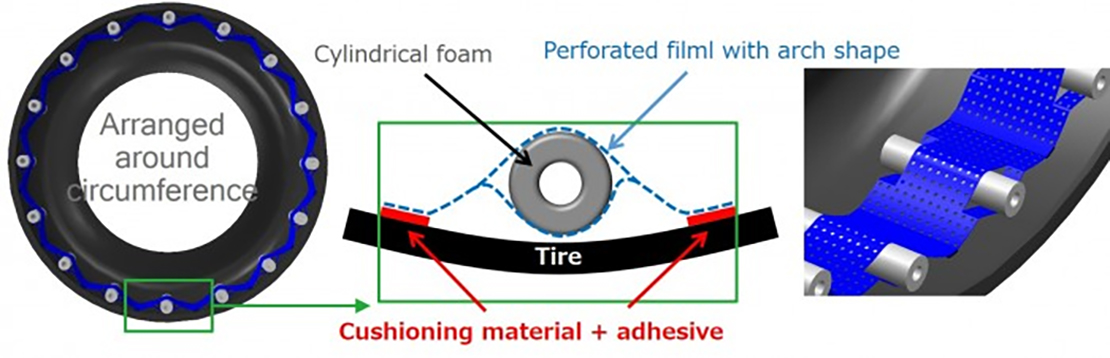

In order to handle the flows in both the vertical and circumferential directions, the break-through point that we devised was to mount an arch-shaped perforated film device.

Also, we arranged cylindrical foam at 16 base points around the tire circumference to hold the archshaped devices. The hollow structure of the cylindrical foam has a sound-attenuation effect. For that reason, a synergistic effect with the perforated film further enhances their noise reduction effect.

■ Effectively reduced noise

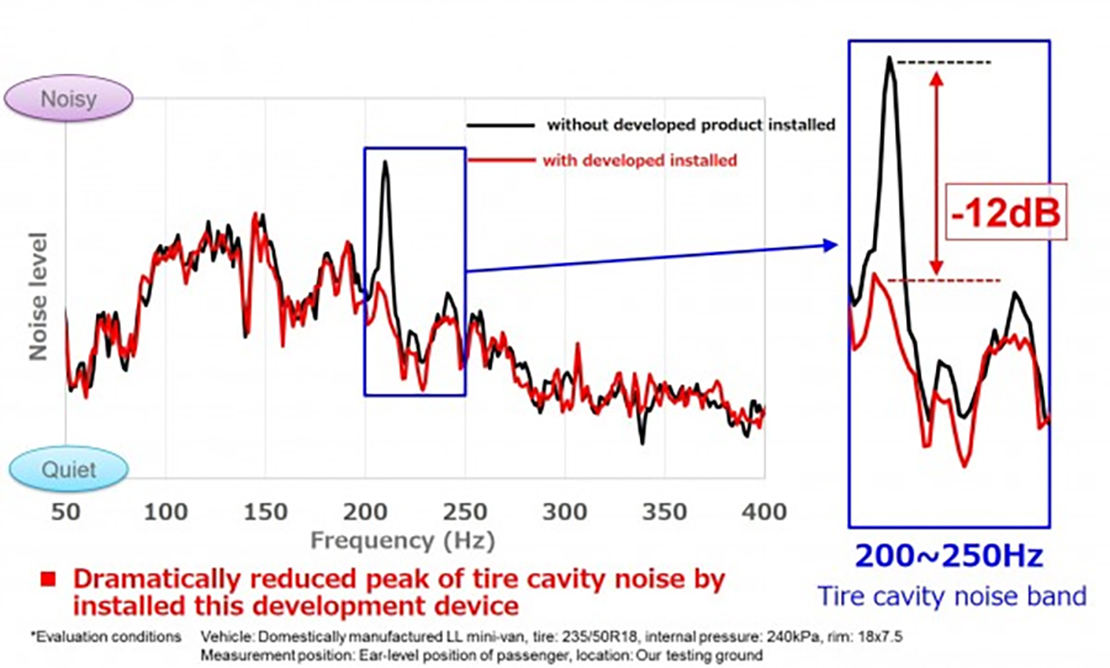

The audible range for humans is said to be approximately 20 Hz to 20,000 Hz. Tire cavity noise is in the frequency band of 200 Hz to 250 Hz.

To check the efficacy of this device in reducing noise targeting this frequency band, we ran actual vehicle tests using tires we manufacture and market. The results of our measurements of noise levels inside the vehicle, showed that tire cavity noise on a passenger vehicle traveling using tires implemented with this device was notably reduce to a maximum level of -12 dB in the frequency range of 200 Hz to 250 Hz, compared to driving on current tires that do not have this device installed. Based on these results, we plan to continue to study commercialization of tires equipped with this device in the future, and to expand the market.

We will continue to evolve tires through technology while continuing our efforts to attain unique technical innovations to develop products required by the next generation of mobility society.

TOYO TIRE & RUBBER CO., LTD. CORPORATE COMMUNICATIONS PLANNING

Hyogo Head office Telephone: +81-72-789-9100 Facsimile: +81-72-773-3272

Tokyo office Telephone: +81-3-5822-6621 Facsimile: +81-3-3865-2240

Toyo Tire published Integrated Report 2025

Toyo Tire integrated report 2025

The Blue Rush

TOYO TIRES Unites Three Legends

Alan Ampudia Wins the Baja 500

Toyo Tires overall winners of 57th edition.

"Prime" rating in ISS ESG Corporate Rating

First time for company to receive rating.

Toyo Tires joins the FIA World Rally Raid Championship

Akira Miura will use Open Country tyres.

The race for more sustainability

More sustainable Proxes race slick tires at NLS

Noair tires used at Oaska-Kansai Expo

Electric carts running on innovative airless tires

Ampudia wins San Felipe 250

Second overall win in consecutive years

Ferrari with more grip and precision

Jean Pierre Kraemer refines iconic Ferrari F355